Classroom Round #03 – The 5S Workshop and Visualization

Disassemble all pens and place them back to the Warehouse. Place the WIP Boxes back to each WIP Out Floor Marking.

Watch the 5S Introduction Video to get a basic understanding of the 5S principle:

Your Tasks in this Game Round

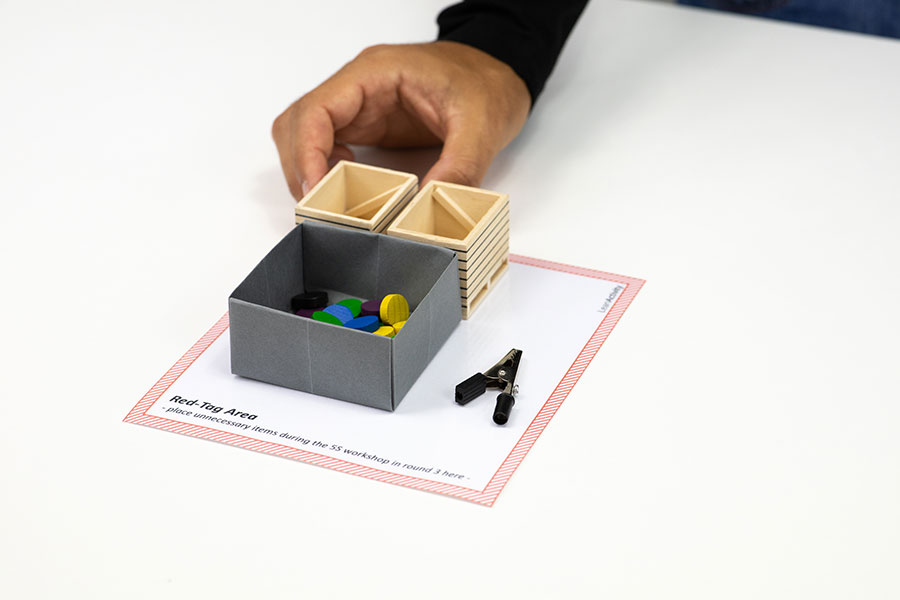

Place the Red-Tag Area inside the plant.

Perform a 5S workshop and remove all unnecessary tools and materials from the plant and store them onto the Red-Tag Area. Clean the stations from dust, rubbish and unnecessary equipment.

Remove Work Instructions #1 and place the Work Instructions #2 on the work stations.

Replace the Material Floor Markings #1 with the Material Floor Markings #2.

Discuss the pros and cons of the 5S method and visualization in the team. How can we ensure the sustainability of 5S measures?

The Red-Tag Area perfectly works in any production site. Place unneeded items here for 30 days. If the item has not been used within 30 days, it is quite certain that the item is no longer required for production and can be removed.

Content of this Game Round

| Red-Tag Area for unrequired materials and equipment |

| Work Instructions #2 for each station |

| Material Floor Markings #2 |

Gameplay Video (5S Workshop)