Do you want to reach the next Level in Lean Management?

Next Level for everyone: from Lean Beginners to experienced Lean Coaches

LeanAcademy

Join the Academy, become a certified

Lean Expert and skyrocket your Career!

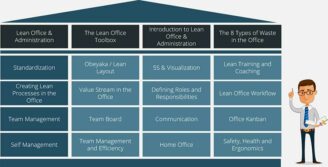

LeanToolboxes

The all-in-one Lean Toolbox

incl. Lean Office Tools, Templates & more

Upgrade to LeanAcademy Certification Program

Upgrade to the LeanAcademy Certification Program to get access to all exams. By passing the exam, you will be officially certified by LeanActivity in all 4 seasons of the LeanAcademy. Use the certification for your CV or your next job application!